Technologies in Supply Chain Systems to Overcome Challenges & Improve Efficiency

With time, technologies are evolving at a rapid pace, and transforming almost every space, and supply chain systems, logistics, and manufacturing sectors are not an exception. Amid growing globalization, increasing product complexity, and evolving customer demands, companies are leveraging advanced supply chain technologies to drive business innovation. The demand and supply of goods have been affected over the past few years, due to an imbalance in the supply chain system, and the key reasons behind the ups and downs in the supply chain system are covid pandemic, war, and other aspects. Such problems have forced businesses to assimilate the latest technology in supply chain management systems to overcome all these challenges and issues.

According to Gartner, more than 50% of global e-commerce companies have invested in AI, and other technologies to improve the supply chain and overcome all the problems. At present, companies are optimizing their businesses by implementing the latest technology and trends so they can efficiently run their business, and increase productivity.

In this blog, we are going to discuss the challenges in the current supply chain system, and key technologies to overcome these issues so that you can clear all your doubts to make an informed decision to implement technologies in your supply chain system.

Let’s start with the key problems in the supply chain system.

Key Challenges in the Current Supply Chain Management System

Due to sudden demands and limited logistics capabilities, supply chains have faced many problems. With time, the adoption of digitalization in the supply chain has been increasing but, still, some challenges have forced information technology in supply chain management. Here, we are going to discuss the key problems in the supply chain so that you can know why technologies are important in the supply chain. Let’s start to know.

• Risks in the Supply Chain

Due to volatility in the markets like changing consumer behavior & demand, climate change, economic uncertainties, raw material shortages, trade wars, policy changes, etc., risks arise in the supply chain.

• Unexpected Delays

In the global supply chains, due to long distances and various steps, unexpected delays. Too much delay is a big issue, and to overcome this issue, incorporating technologies in supply chain becomes inevitable.

• Cost Control

Cost is another big issue, and the cost of energy, freight, raw materials, and labor is increasing with time. To ensure operations without delay & interruptions, and continued delivery of goods and services at good rates – businesses must control the cost. Technologies play an important role in controlling costs. By integrating technologies in supply chain you ensure on-time delivery, proper management, reduced human interference, save energy, automate the process, and many more. All that helps you to control the cost.

• Collaboration of Data Across the Supply Chain

To efficiently manage your supply chain, you have to rely on data, and in the global supply chain, every day tons of data are generated, and getting the best information from that data is not an easy task. To access the data, you have to rely on the technologies that will offer you the best results from the data. However, managing data is still a tedious task in supply chain management.

• High Freight Prices

Energy prices are increasing and with time, the demand for container shipping is also increasing, all of which have pushed freight prices. Increasing cost is also a big problem in the supply chain system.

• Difficult Demand Forecasting

The Covid pandemic and other aspects have made it difficult to forecast the demand, and that’s why, estimating the numbers for manufacturing and the inventory to be stocked becomes a challenging task. This is a serious problem in the supply chain, and with the use of technology, we can do it appropriately.

• Digital Transformation

To transform your supply chain business in the digital world, technologies like AI, IoT, Blockchain, Cloud Computing, Automation, Robotics, etc. are a must. The prime issue is to implement these technologies in their existing supply chain operations.

• Port Congestion

Due to the pandemic, freight loading and unloading operations were restricted, and all that led to port congestion. That’s why, dispatches and delivery are delayed. All the instances have forced businesses to redesign their operational strategies to successfully run this business without facing any issues.

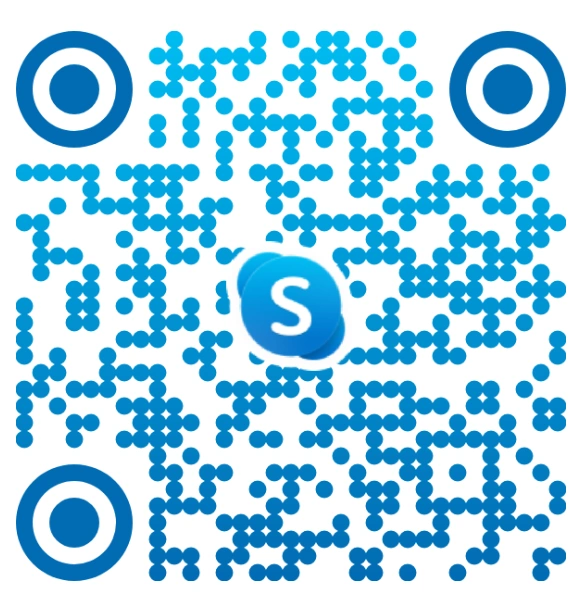

Top 5 Technologies Shaping Next-Gen Supply Chain Management Systems in 2024

The use of technologies in supply chain management systems is improving accuracy, efficiency, and velocity. Advanced technologies such as Artificial Intelligence (AI), Machine Learning (ML), Internet of things (IoT), Blockchain, Data Analytics, Cloud Computing, Generative AI, AI in ERP chatbots, etc. are making the supply chain more advanced and smart. Let’s start by learning about the most advanced information technology in supply chain management and their roles.

1. Internet of Things (IoT)

The Internet of Things technology in supply chain & logistics helps you to automate the process and streamline tasks across the supply chain system to get high ROI and eliminate losses. IoT is transforming complex supply chains into connected networks, and this way, handling your business becomes so much easier. You can understand it with the example of a warehouse where an e-commerce company handles thousands of orders in a day. In this, the warehouse gets data from IoT devices that automatically get an alert for new orders, and the quantity of product of a particular order is also tracked automatically, after the order is placed, stock replenishes automatically. In the whole process, there is no human intervention. This is one of the examples of IoT transformations in supply chain systems and logistics.

The best part of IoT is it helps businesses to manage unprecedented situations. Let’s have a look at the key benefits of using the Internet of Things technology in supply chain management and logistics.

- Track real-time location

- Monitor storage condition

- Locate goods within the warehouse

- Improve contingency planning

- Enhance total supply chain performance

- Better segmentation of goods

- Process automation

- Optimum Utilization of Assets

- Improved Customer Experience

2. Blockchain

Blockchain is known for its immutable nature which makes it the best fit for the supply chain management and logistics industry. At present, blockchain technology has become a must-have part of the supply chain management system to stop unauthorized and fraudulent activities and help you maintain the overall integrity of the supply chain.

Blockchain technology in supply chain management offers you the best way to audit trails that is much more efficient than the traditional approach. In short, blockchain optimizes supply chain operations and fosters trust among stakeholders.

It is a digital ledger that records transactions, and due to decentralization no one controls it, and it is also immutable which means once a transaction has been recorded, no one can alter it. In this, each link or block is linked to the previous transactions, and whenever any changes happen, it will be changed in all blocks. This way to change any record, you have to make changes in all records. That’s why it is the best. All these attributes make blockchain the best for enhancing supply chain management.

Let’s have a look at the key benefits of blockchain technology in the supply chain management and logistics industry.

- Enhanced Transparency

- Improved Traceability

- Greater Efficiency

- Increased Security

- Better Collaboration

- Cost Reduction

- Sustainability Tracking

Also Read: The Role of Blockchain for Secure & Accurate Supply Chains

3. Artificial Intelligence (AI)

Artificial intelligence technology in supply chain management systems is playing a vital role in boosting the overall efficiency and performance of the business. Generative AI has transformed the supply chain by simplifying inventory management, production timelines, and shipping routes. It helps in analyzing data to detect irregularities, patterns, and potential frauds within the supply chains. You can also train AI models for a specific task to improve its efficiency. At present, supply chain networks come with huge data, and finding helpful information from that AI is very beneficial.

By integrating the latest technologies like AI, ML, Blockchain, IoT, Predictive Analytics, etc. in supply chain management and logistics, businesses can automate their warehouse operations and improve overall efficiency by better delivery times, optimizing the sourcing relationships, and managing their inventory proactively. The best part of AI in the supply chain is that businesses can get insights on a microscopic level from huge data, and managing business becomes so much easier without human involvement. It is one of the key reasons behind the use of AI in supply chain and logistics.

Here is a list of the key advantages of AI technology in supply chain management.

- Reduced operating costs

- Improved warehouse efficiency

- Improved supply chain sustainability

- Inventory management

- Faster and punctual deliveries

- Improved worker and material safety

4. Robots and Automation

Robots are playing an important role in supply chain technology. The main use of robots in the warehouse is to move materials from one place to another and order the fulfillment process. By using AI, robots have become advanced and they are doing manual human-driven tasks such as picking and packing orders, managing the warehouse, replenishing the orders, fulfilling the stocks, etc. to automate the supply chain technology.

According to the IDC, around 65% of warehouse activities are managed by robots, and that’s why humans and robots are leading the supply chain industry through automated supply chain management solutions. With time, robots are becoming more advanced, and in the near future, we will experience a more streamlined process of supply chain management.

Let’s start to know the key advantages of implementing robots and automation in supply chain management and logistics.

- Reducing error

- Increasing productivity

- Streamlining operations

- Improving customer satisfaction

- Improving warehouse management

- Improving supply chain planning

- Improving customer service

5. Cloud Computing

In the supply chain system, tons of data is generated, and AI-based cloud computing is used by businesses to convert that data into helpful information. This technology allows companies to store their data on a centralized platform so that they can access it from anywhere and anytime, and the best part of this technology is that it optimizes every step of supply chains, and you can enhance efficiencies of the supply chain system.

When cloud computing is assimilated with artificial intelligence in logistics and supply chain management then it transforms the whole process and complex processes become so much easier. With time, the demand for cloud computing is increasing to make business processes more streamlined and faster.

Here is a list of key functions that become so much easier when you use cloud computing technology in supply chain management.

1. Managing logistics

2. Automating inventory management

3. Making plans and predictions

4. Improving procurement and sourcing

5. Managing maintenance and equipment breakdowns

6. Expanding collaboration opportunities

7. Supporting multisite visibility

Integrating these technologies in supply chain domain businesses not only makes their process transparent, lowers the delivery time, and improves overall efficiency but also can predict the demand. That’s why, to overcome challenges businesses are integrating these technologies into supply chain systems.

Now, let’s discuss the advantages of using technologies in the supply chain and logistics.

What Are The Key Benefits of Using Information Technology in Supply Chain Management Systems?

Assimilating technologies in supply chain management systems significantly add value to your business, and you get various benefits like low cost, faster speed to market, less human intervention, revenue growth, automatic processes, etc. Supply chain management technologies make a powerful impact on business directly and indirectly, and you get optimized processes, and better results that reduce the resources, energy, and human resources, and ensure profitability, fast time, and high ROI. Let’s have a look at the advantages of using technologies in supply chain management.

- Amazing customer experience

- Lower cost of operation

- Increased speed to market

- Improved Production Efficiency

- Improved Inventory Management

- Less requirements for human interventions

- Improved Communication and Collaboration

- Faster adaptability to market changes

- Improved Order Management

- Faster reactions to supply chain threats

- AI and Advanced Analytics

- Robotic Automation

New Technologies Trends in the Supply Chain in 2024

Supply chain disruption is an important factor that cannot be ignored. After the covid-19, we have seen a huge upsurge in the supply chain management system, and technologies are playing a vital role in it. Key technologies like AI, Blockchain, ML, Automation, Data Analytics, IoT, Cloud Computing, etc. are giving a perfect shape to the supply chain industry. At present, and shortly, we will experience a lot of new technological aspects that will transform the whole supply chain industry by making it more efficient.

Here, we have made a list of the 10 technologies in supply chain management that are shaping the future of the supply chain industry in 2024. Let’s start to know them.

1. Cybersecurity and data governance

2. Artificial Intelligence (AI) and Machine Learning (ML)

3. Sustainable and circular supply chains

4. Digitization and IoT integration

5. Big data and advanced analytics

6. Robotics and automation

7. Augmented workforce and intelligent automation

8. Supply chain visibility and traceability

9. Elastic and agile logistics

10. Advanced cybersecurity measures

Why Choose Amplework to Implement Technology in Supply Chain Management?

Amplework is a leading company that is known to offer top-notch software solutions across all industries. They have an experienced team of developers and designers who have rich working experience in the latest technologies such as AI, Blockchain, Generative AI, Cryptocurrency, Cloud Computing, Machine Learning, etc. and many more. Within a short period, this company has become the talk of the town to implement technology in supply chain management to overcome all the challenges and issues. They have transformed a wide range of supply chain systems by integrating all the latest tech stacks and trends in their system. If you are running a supply chain system, and want to transform it into the digital world, or you want to integrate key technologies in a supply chain system to boost its performance, contact Amplework.

Amplework is a prominent AI-based mobile app development company that is transforming all kinds of businesses with its innovative software solutions. For all kinds of software development services, share your ideas with them.

Final Words

Artificial intelligence-based technologies such as machine learning, automation, predictive analytics, blockchain, IoT, cloud computing, etc. have the potential to transform the supply chain management system. And, we have been experiencing a lot of fruitful changes in the supply chain system after implementing the latest tech stacks and trends in it. At present, due to AI-powered technologies managing supply chain systems has become so much easier and more fruitful. With time, as technologies evolve, we will experience more fruitful aspects that will change the entire supply chain industries and organizations, and all the problems in the supply chain system will be resolved. For an efficient supply chain system, technologies are playing an important role, and helping businesses to achieve their objectives easily.

Frequently Asked Questions (FAQs)

What are the Top 7 Technologies Shaping Supply Chains into a Strategic Business Function?

Technologies are making a significant impact on every business and process, and making them more productive, and easy to handle. Digitization is also making an impact in the logistics and manufacturing sectors. To make your business more fruitful, the supply chain must be digitized, and at every stage, we must use technologies so that we can automate the process, and improve efficiency. Because a huge amount of information, and data is generated across various supply chain functions, and to make the best use of this data, technologies in supply chain management play a vital role.

Let’s have a look at the top technologies that are shaping supply chain management systems that are accelerating the transition and shaping the next-generation supply chain.

- Cloud computing

- Artificial Intelligence

- Generative AI

- Robotic Process Automation

- Big data

- Internet of Things (IoT)

- Digital twin

How Does Technology Improve Supply Chain Management?

When you use technologies in supply chain management then it comes with numerous benefits. Let’s start to know a few of them.

- Real-Time Visibility

- Automation and Efficiency

- Data Analytics and Insights

- Demand Forecasting and Inventory Management

- Enhanced Order Tracking

- Communication and Collaboration

What are the Key Challenges in Implementing AI & Other Technologies in Supply Chain Management?

AI, ML, Data Analysis, Predictive Analytics, Blockchain, Cloud Computing, etc. in the supply chain offer a wide range of benefits and other opportunities for businesses. But, still, companies face challenges. To get the maximum benefit from AI in supply chain operations and logistics, you have to deal with these challenges. Let’s start to know some of the challenges.

- Legal & regulatory considerations

- Legacy systems & static infrastructure

- Lack of clear transformation strategy

- Data quality & integration

What are the Key Technologies to Overcome Challenges in Supply Chain Systems?

Here is a list of the technologies that are used to improve the supply chain system.

- Artificial intelligence

- Blockchain

- Cloud computing

- Data Analytics

- Robotics and automation

- IoT

How to Overcome Problems in Implementing AI Technology in Supply Chain Management?

Technologies can help you overcome supply chain problems if you have the proper tools to track real-time data. To track the data, you have to use IoT devices, sensors, and RFID ( Radio Frequency Identification) tags in the supply chain so that you can collect data and analyze them. You can also use AI-powered APIs to overcome the complexity of current supply chain systems. The best part of APIs is that data can be communicated and shared in the system to ensure compatibility and scalability.

sales@amplework.com

sales@amplework.com

(+91) 9636-962-228

(+91) 9636-962-228